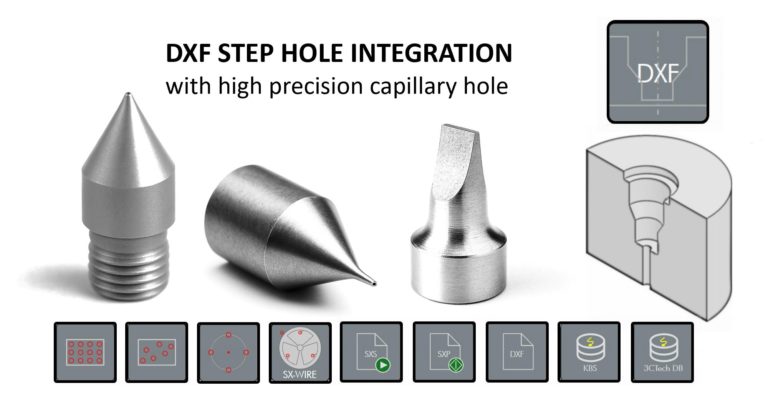

High precision Step Hole Drilling integration on SX30 machine

The SX30 machine, equipped with the new Basic interface, enables intuitive operation and quick drilling mode selection. It is designed to handle both simple and complex hole geometries—including step holes and high-precision capillary holes—while optimizing production efficiency.

The Basic SARIX software with DXF Step file integration feature automatically interprets the imported geometry and generates the corresponding electrode path. This ensures that drilling is executed precisely on the defined diameter sizes while maintaining perfect junction alignment between diameters.

By eliminating the need for manual programming, this function improves accuracy, reduces setup time, and guarantees consistent machining quality even for complex profiles.

High precision capillary hole

on nozzles feature orifice diameters between 0.05 to 0.1 mm, aligning with micro-dispensing requirements

Facts & Results

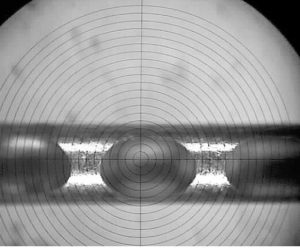

- Achieving sub-50 µm holes without cracks or burrs.

- Capillary orifice tolerance ±0.002 mm

- Surface roughness below Ra 0.15

- Concentricity within 0.002 mm

- Maintaining repeatability across thousands of nozzles.

- Hole-depth-to-diameter ratios up to 100:1 using SX-MDH device

Market application

- Electronics Manufacturing

- Medical & Biotechnology

- Automotive & Aerospace

- Optics & Photonics

- Micro-gluing

- Conductive ink dispensing

SAMPLE SELECTION

We meet your most demanding micro drilling challenges!

Contact us for a free sample test!