____________________________________________________________________________________

SP12 Collet system with collet changer

The SP12-AC collet changer is a quick-change system for up to 4 collets of varying diameters, significantly cutting down machine setup time.

This system eliminates the need for realignment when switching collet types or electrode diameters.

A collet change for a different diameter electrode takes less than 30 seconds, while collet alignment remains intact throughout changes.

SP12 Collet

High precision quick collet changer

with automatic electrode feeding

and electrode wear compensation

Runout/tilt adjustment

Internal high pressure flushing

Diameter range Ø 0.05 to Ø 1.5 mm

Up to Ø 0.99 it fits to clamping range of 0.04 mm

____________________________________________________________________________________

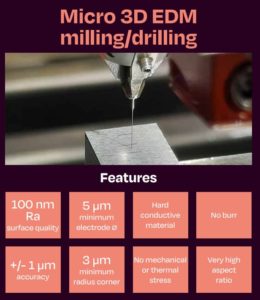

High performance Micro EDM Milling Technology.

SARIX 100% Swiss-Made Technology

Fully Programmable 3D Machining Process

No need for die-sinking or pre-shaped electrodes. The system enables direct 3D machining for maximum flexibility and efficiency.

Automatic Real-Time Electrode Wear Management

Ensures consistent precision and extended electrode life by continuously monitoring and adjusting for wear during operation.

Intelligent Electrode Reconditioning

For micro or intermediary-sized electrodes, automatic reconditioning maintains precision and performance without manual intervention.

Ultra-Fine Electrode Shaping

Electrodes can be shaped down to 10 µm, ideal for high-precision micro-manufacturing.

Laser-Measured Accuracy

Integrated laser measurement allows ultra-precise machining with tolerances as tight as ±1 µm.

____________________________________________________________________________________

MTD Micro Molding Testimonial:

“High-resolution features created with ultra-precise tools result in superior products. In-house tools mean a shorter, more robust development process.”

Our Sarix 3D micro EDM machine is a very unique machine that creates cavity geometry by following a toolpath similar to CNC milling, but the main difference is that the end mill is actually an electrode that can be as small as 5 microns.

____________________________________________________________________________________

Sirris testimony:

“3D micro-EDM-milling technology pushes the limits of micromachining, allowing the creation of high precision 3D micro-structures, whether they are complex positive or negative shapes.”

“The accuracy of the electrode in-situ grinding module combined with ultra-high precision spark generators allow the creation of cavities as small as a few tens of microns wide, with quasi-optical surface finishes and aspect ratios up to 1:50. Very hard, electrically conductive materials can be processed without any burrs, or thermal or mechanical stress.”

____________________________________________________________________________________

SX-COBOT

The SX-COBOT automation cell integrates all process elements, including electrodes, guides, tools, and accessories. Beyond workpiece loading, the robot can switch drilling diameters, transition from guide-assisted drilling to 3D Micro EDM Milling, load measurement equipment, or perform additional flushing operations.

Utilizing RFID tags on all components, the system minimizes

machine downtime and enables round-the-clock operation, including unmanned night or weekend shifts